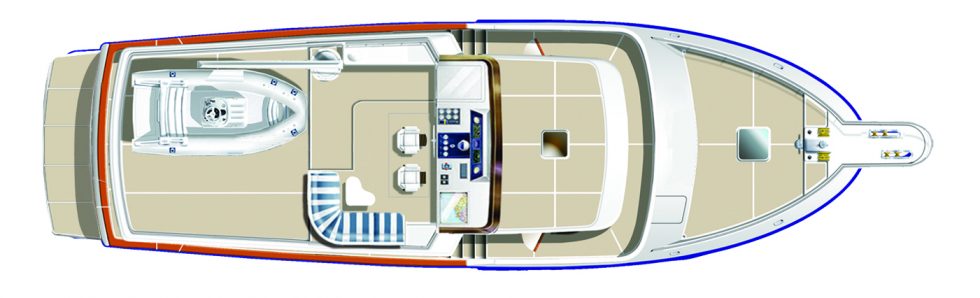

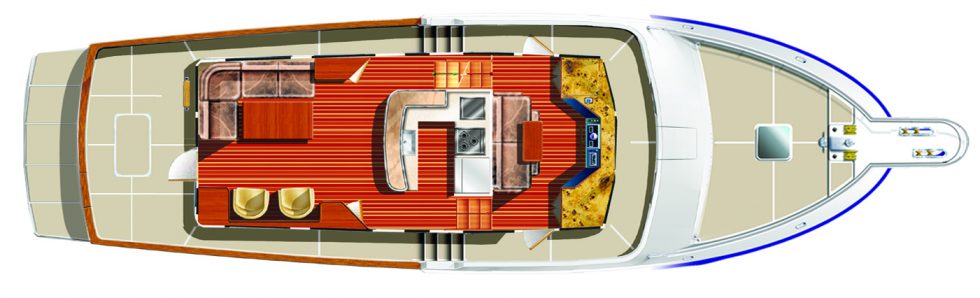

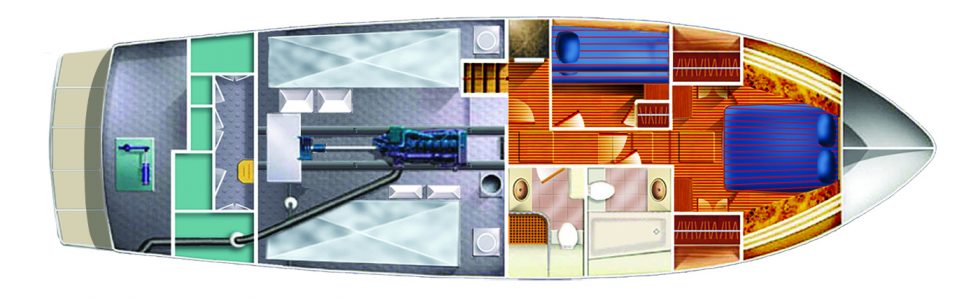

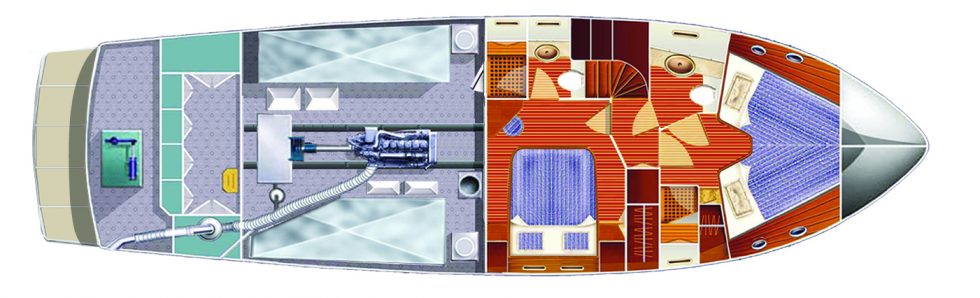

The Selene 49 is the next generation evolution of the very popular Selene 47. It features the Deep-Hull™ design and Cruiser Stern™ which improves headroom in the engine room and lazarette and makes the hull even more efficient than its predecessor. The Selene 49 has a very traditional « salty » look from the outside. Another significant difference is a wider flybridge giving space for entertaining friends and family with style in the open air, with ample room on the aft deck for a dinghy and hydraulic crane. The flybridge layout with a canvas cover or a hard-top includes an L-shaped settee and table and a bar with sink and BBQ. The hull itself is deeper than the Selene 47 and is meant to carve through the water. The longer LOA of the Selene 49 translates to an 8” increase in the cockpit and 4” more in the salon. The living space is large and spacious for the long cruising days. The salon is luxuriously finished in teak. Past the L-shaped dinette for four to port, the U-shaped galley forward has granite countertops and modern appliances, including a full-size refrigerator with freezer. The two or three-stateroom accommodations down below are spacious, due to the full hull sections forward. The master stateroom has a queen-size island berth with teak and holly steps on both sides, plus two large cedar-lined hanging lockers.

Selene 49

2,000 NM RANGE

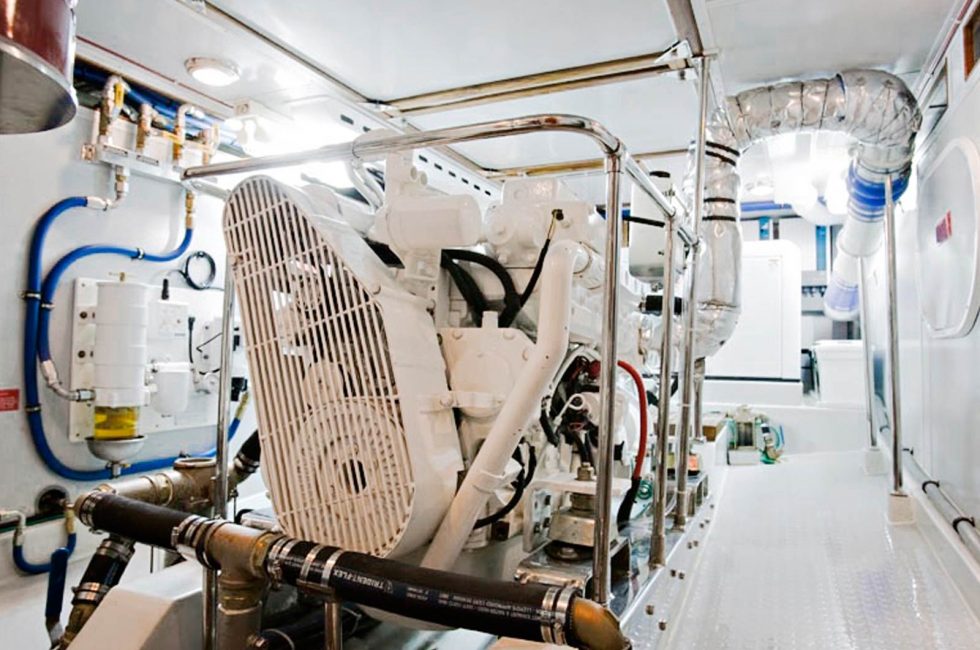

Headroom for the engine room has increased by a whole foot and the John Deere 6068AFM85 230HP@2300RPM engine is standard. The Selene 49 is an excellent long range cruising boat with a D/L ratio at full load of 316, and A/B ratio at full load of 2.54. At 1,800 rpm, the Selene 49 has a cruising speed of 8.5 knots for a range of 2,000 nautical miles. The 49 also boasts an integral swim platform with a telescopic swim ladder, and beneath the 18″ hull extension Cruiser Stern™ there is extra room in the lazarette for storing gear and supplies, and at the same time greater buoyancy to offset the weight of the larger flybridge. As the flagship of the smaller Selenes, the Selene 49 boasts a level of luxury normally only found on its larger sisters in the range, but all in an affordable package that’s easy to handle as a couple.

Do not hesitate to contact us for more info : [email protected]

TECHNICAL SHEET

- LOA : 51’-110’ (15.80m)

- LWL: 46’-10’’ (14,27m)

- Beam: 15’-8’’ (4,78m)

- Draft: 5’-11’’ (1,8m)

- Air draft mast down: 14’-2’’ (4,32m)

- Displacement: 67,240Lbs (30,5t)

- Fuel tank capacity: 1,300 USG (4 921 L)

- Fresh water tank capacity: 210 USG (807L)

SELENE 49 ADVENTURES

John and Tracey are residents of Nevada and have called Las Vegas home for well over 25 years. Between the two of them, they have three boys and four grand-kids. They take one day at a time and focus on traveling at their own pace. Pairadice is a Selene 47 Ocean trawler. They acquired her in May 2015. The Selene 47 Ocean Yacht is now replaced by the Selene 49 Ocean Yacht, a very popular model frequently operated by couples. Selene 49, hull #42 will be launched in a few days at the shipyard. Read more…